Hardware in the Loop Testing for Embedded Systems Development

June 09, 2025

Blog

Testing new hardware can be one of the most challenging parts of developing IoT and embedded systems. Hardware systems are complex, relying on multiple integrated components, including sensors, microcontrollers, communication modules, and power management systems. Each of these components requires rigorous validation.

IoT devices operate in diverse and often unpredictable environments. They must handle various combinations of sensor inputs reliably. They are used in dynamic environments with fluctuating inputs and varying power availability, all of which makes real-world simulation challenging.

This is further complicated by challenges in simulating real-world environmental scenarios such as motion, vibration, extreme temperatures, water flow, and other physical inputs. Unlike traditional software testing, IoT hardware validation requires extensive testing of real-world scenarios, making automation difficult and increasing the time and cost of validation.

Hardware in the Loop (HIL) Testing

Hardware in the Loop (HIL) testing is a method used to test complex embedded systems. It works by connecting an embedded device to a hardware test system that mimics the real-world conditions under which the finished product must operate.

A HIL testing device streamlines the verification of functionality, reliability, and performance of hardware components, without manual intervention. Hardware in the Loop testing is a crucial technique for the validation of embedded systems.

A HIL testing device works by providing real-time simulation of environmental inputs with actual hardware components to evaluate system performance under realistic conditions. The embedded device is connected to a HIL simulation environment that mimics real-world inputs and interactions. Engineers can then test control algorithms, hardware interfaces, and system responses without needing a fully developed physical system. This helps identify issues early in the development cycle, reducing costs and improving overall system reliability. It is especially critical to simulate complex interactions between environmental inputs that are difficult or costly to reproduce in a lab environment.

One of the key advantages of HIL testing is its ability to create repeatable and controlled test scenarios, allowing engineers to assess the behavior of embedded devices in both normal and edge-case conditions. HIL systems provide scripting support for test scenarios, allowing engineers to create a suite of tests to automate testing. This allows repeatable testing during development and release cycles.

|

Type of Device |

Simulated Inputs |

Behavior to verify |

|

Water flow control device |

Fluctuating flow sensor readings |

Proper valve control (opening and closing valves at the proper time) |

|

Automotive ECU |

CAN bus inputs |

Proper response to commands received on the CAN bus |

|

Smart home alarm system |

Motion sensors |

Proper alerting when system is armed, logging of events but not triggering of alerts when system is disarmed |

HIL testing use cases

How a HIL testing solution works

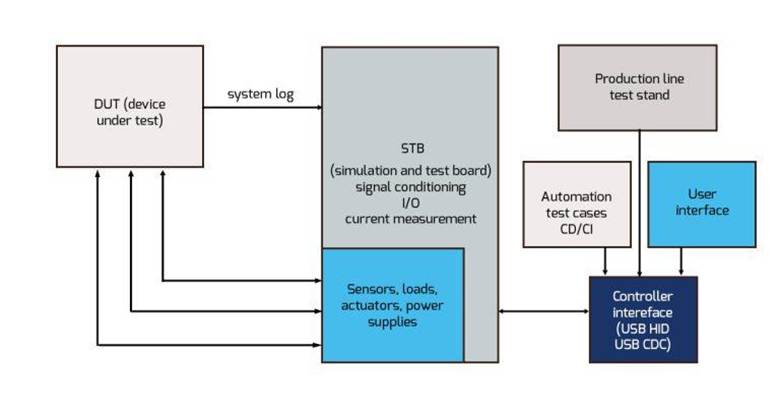

The HIL Test System can be used to automate hardware testing during the CI/CD cycle, for systems integration testing, and for validation of products during manufacturing.

The capabilities provided by a HIL system vary based on the requirements of the system being developed. However, all HIL systems include three key capabilities, simulation of inputs, monitoring and recording of system behavior and outputs, and an API for controlling and configuring tests.

A HIL testing solution would typically provide simulation of:

- External power supply

- Battery power supply (variable voltage, battery drain simulation for simulating low battery conditions or power loss)

- Pulse generation for flow sensor simulation

- Resistive sensor simulation

- Button presses

To enable validation of the device’s function, a HIL solution provides monitoring and recording of outputs such as:

- Precise current consumption

- Actuator outputs

- System logs

Specialized HIL systems for automotive or industrial control systems would also provide support for domain specific interfaces such as Modbus, SPI, CAN, Ethernet, LIN, or RS-485.

By providing scripts or an API for controlling and configuring tests, engineers can build a set of tests to allow validation of specific features, or full verification of device functionality.

HIL enclosure with the4 HIL PCB integrated into the test stand. The PCB under test, in this case a small PCB board, is installed on the top and the placement arm holds the device under test in place during the testing process. The PC runs the HIL test application which runs test scripts and records tests results.

HIL enclosure with the PCB under test inserted into the test enclosure

HIL Testing for Development Teams

Development and quality assurance teams can use HIL testing as part of their ongoing CI/CD cycle including nightly or weekly hardware regression tests. The HIL system can be used by both hardware and firmware developers to verify functionality. New features are validated as part of daily integration testing cycles. This ensures issues are found early in the development process when they are easier and less costly to fix. Additionally, as new features are developed, tests can be added to the test suite to create more complete validation processes.

HIL Testing for Production Line Validation – using the same HIL device used for both production line validation & development testing

Validation of products during manufacturing and assembly is critical to ensure the quality of the end-product. The same HIL testing device that is used by engineering and QA teams can be used to validate products after production. Real-time testing as products as they the manufacturing process completes provides early detection of problems. Any defective components or faulty manufacturing processes are discovered while products are still in the manufacturing facility and can be resolved before shipping products to customers. Even testing a small sampling of products can ensure defects are discovered.

If a problem is found, manufacturing can be paused while the issue is diagnosed and resolved. As a result, manufacturers can achieve significant cost savings. Without real-time production testing, problems can remain undetected, resulting in the production of a large number of faulty units. Additionally, resolving issues before they are shipped to the customer dramatically reduces the product returns and improves customer satisfaction.

Summary

A HIL testing device streamlines the verification of functionality, reliability, and performance of hardware components and reduces the need for manual intervention in repetitive testing tasks. The system provides execution of predefined test cases, captures results, and provides data to analyze system behavior. This reduces human error, increasing test coverage, and enables continuous testing throughout the development cycle. Automated hardware testing is particularly valuable for complex embedded systems, ensuring consistent quality and accelerating time to market.

Since real-world testing can be expensive and time-consuming, HIL provides a safer and more efficient alternative for verifying software and hardware interactions. By simulating sensors, actuators (e.g., motor drivers, valves, or LED indicators), and external environments, HIL testing ensures that an embedded system meets design requirements before full deployment, leading to improved safety, performance, and development efficiency.

About ARS Embedded Systems

ARS Embedded Systems helps companies build electronic products for use in harsh environments, security products, water and heating control, and other IoT applications. They have expertise in both hardware and software design for Sensors, IoT, Control, and Wearable devices, and can assist with building products compliant with regulations including Cyber Security Act (CSA), Cyber Resilience Act (CRA), and Radio Equipment Directive (RED).